The Citizen 8810 family of watches are often mentioned briefly in discussions about vintage electro-mechanical or vintage quartz watches. Perhaps because they are rare beasts, they don't seem to get the recognition they deserve. Released in mid-1973 it was Citizens first Quartz watch but was only in production for about 6 months before the much more conventional Crystron-era step-motor quartzes emerged early in 1974. Production volumes during this brief time seem to have been pretty low.

For the uninitiated, this is a quartz-controlled balance wheel movement. That means that it uses a battery, quartz crystal and some electronics to drive and regulate the oscillation of a balance wheel which then drives a conventional mechanical drive train. There were only a few manufacturers that made this type of movement but no one made one quite like this Citizen. Unlike some other quartz-controlled balance movements this is a real high-quality thoroughbred . The quartz part is temperature compensated meaning 10s/month accuracy in the 8811 version (shown here) and 5s/month accuracy in the very rare 8810 EFA version. And the mechanical part beats really, really fast...

I've had a brown/gold dial version in my 'A-list' box for a while. Seen here on one of the three original strap types that these watches were available with -

![Citizen%208811%20-%20B_zps9vmh0ovw.jpg Citizen%208811%20-%20B_zps9vmh0ovw.jpg]()

![Citizen%208811%20-%20A_zpscnmb2laz.jpg Citizen%208811%20-%20A_zpscnmb2laz.jpg]()

I've had another one waiting in my inbox for service/repair for rather too long - today I stripped it and repaired a couple of faults. So I thought I would take the opportunity to post a few pictures of the movement and to point out a few interesting (for some) technical details.

Citizen describe the coil/balance/index mechanism as a 'resonant motor' - the balance mass/spring has a resonant mechanical frequency and it is forced electromagnetically at this frequency by a coil pair attached to the output of the electronic circuit and four pairs of permanent magnets mounted on the balance. The balance is small and the spring is stiff providing a ridiculous 115200 A/h (16Hz) blur. It doesn't take much dirt or misalignment to stop this thing from running properly. It also provides the kind of smoothly sweeping second hand one usually associates with a hum.

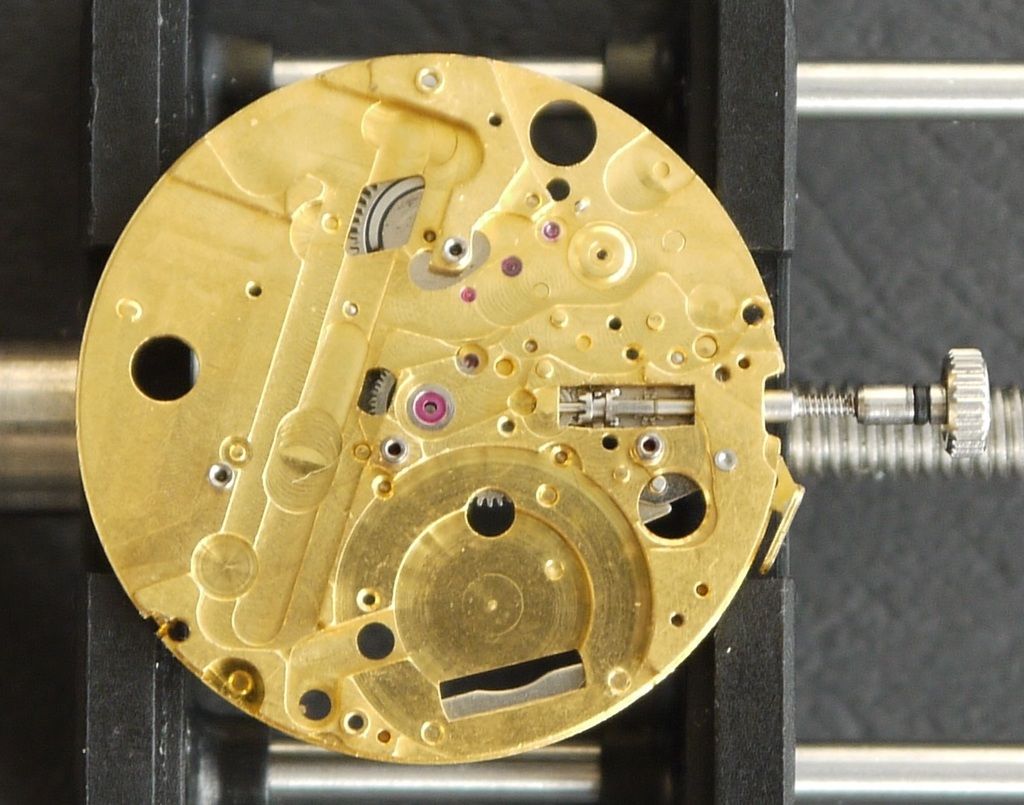

The drive train is extremely compact to allow for the large battery, enormous quartz tube, electronics, coil assembly and ancillary elements. This shows the bare movement plate (balance side) -

![8811%20-%20Circuit%20Side%20Bare_zpsuply 8811%20-%20Circuit%20Side%20Bare_zpsuply]()

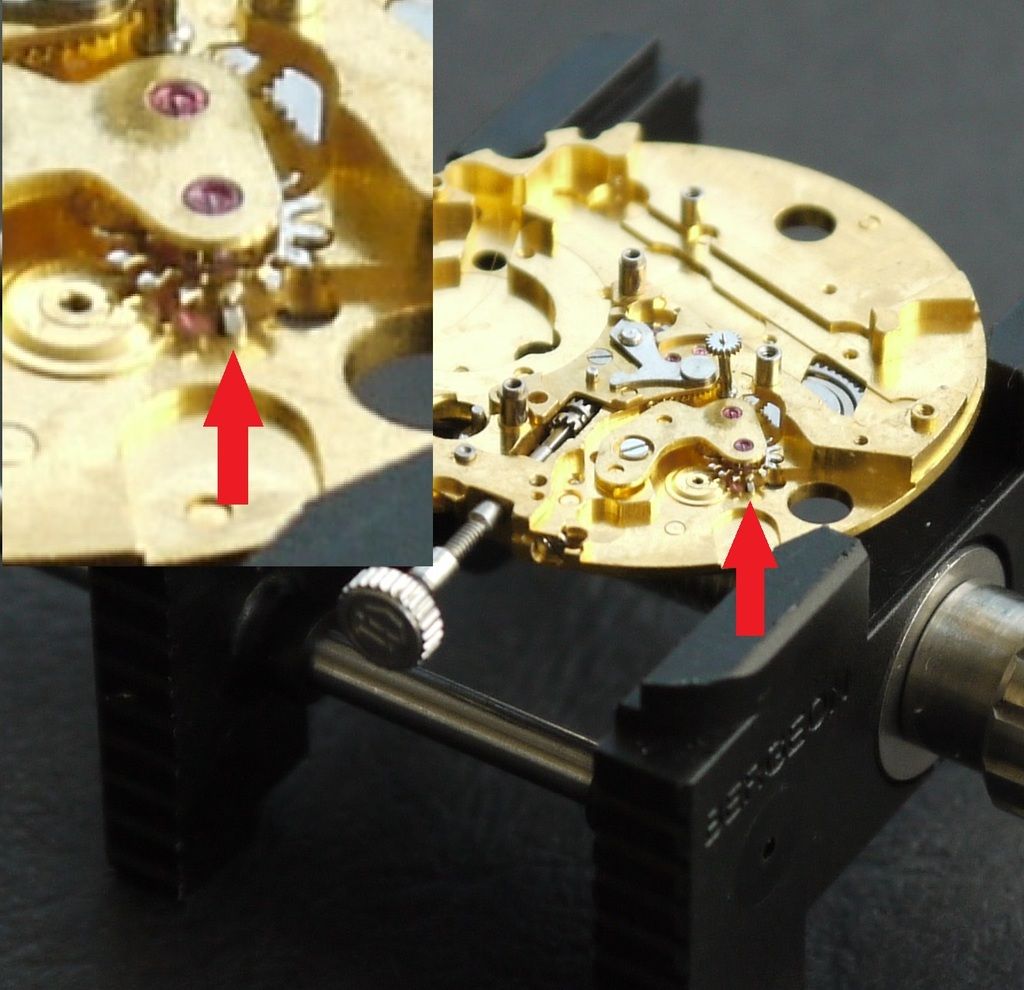

Here it is with the complete drive train fitted -

![8811%20-%20Circuit%20Side%20Drive%20Trai 8811%20-%20Circuit%20Side%20Drive%20Trai]()

The build quality and design detail is impressive. Coils are elliptical to better couple with the permanent magnets on the rotating balance -

![8811%20-%20Coil_zps5gawwvzp.jpg 8811%20-%20Coil_zps5gawwvzp.jpg]()

The coil assembly slots in between the two layers of magnets on the balance and must be shimmed accurately with special parts at both ends to the correct position. The balance cock with serial number and markings fits directly on top of the drive train bridge. The regulator can be used to adjust the resonant frequency of the balance and so adjust the AMPLITUDE -

![8811%20-%20Balance%20Coil%20and%20Shims_ 8811%20-%20Balance%20Coil%20and%20Shims_]()

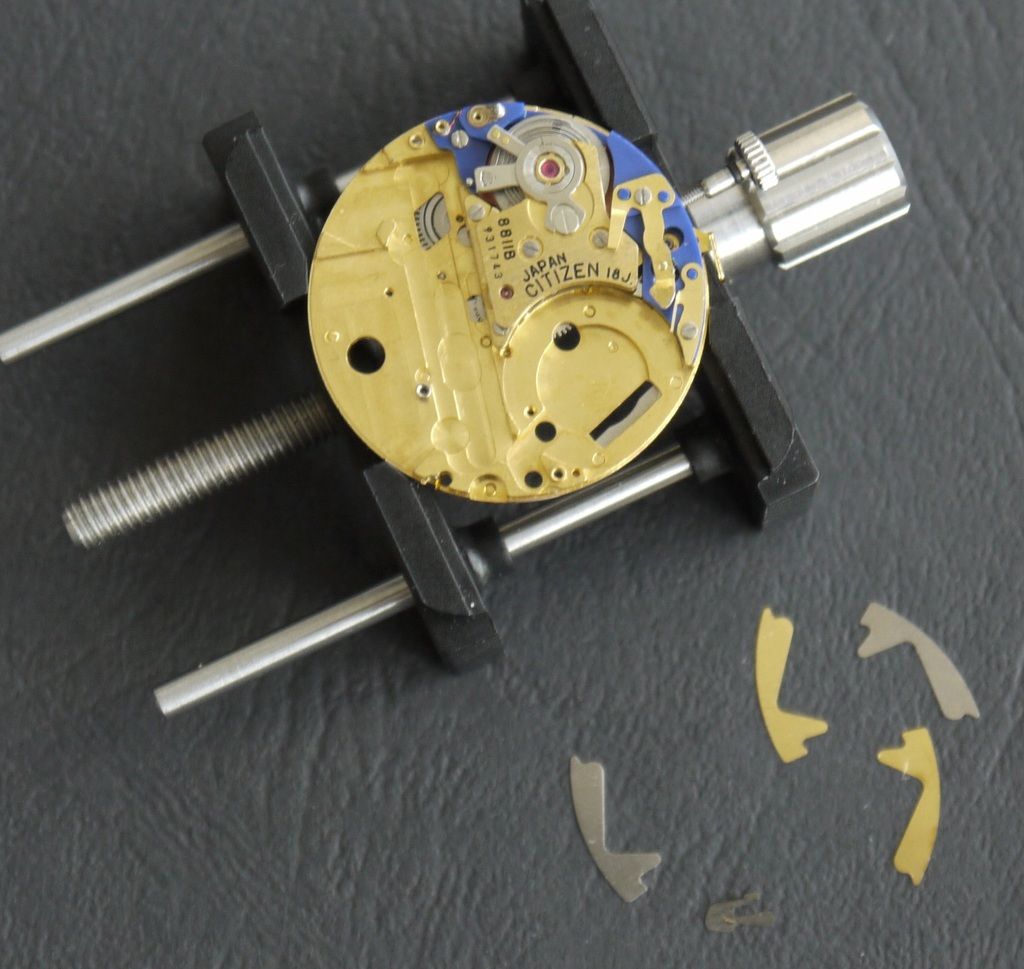

CMOS electronics were provided by Toshiba -

![8811%20-%20Circuit_zpsmgtsnlue.jpg 8811%20-%20Circuit_zpsmgtsnlue.jpg]()

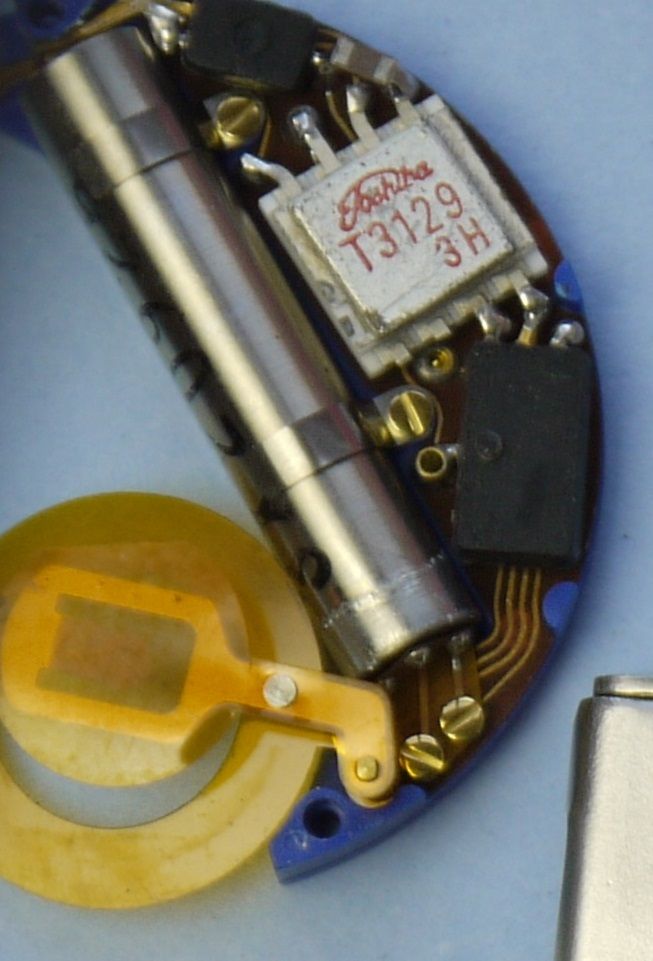

The movement has an unusual escapement much like that found in some early electric watches. There is a roller jewel on the bottom of the balance which directly drives the toothed index wheel. Then there is a small permanent magnet fixed in the movement plate which keeps the index wheel advancing forward in orderly fashion one tooth at a time.

View of the index wheel with permanent magnet highlighted -

![8811%20-%20Index%20Magnet%20B_zpsnp7xgpl 8811%20-%20Index%20Magnet%20B_zpsnp7xgpl]()

The movement contains a rather unusual sweep second pinion assembly with a cam section and a separable clutch. There is an elaborate mechanism that separates the sweep second drive and simultaneously engages a hammer onto the cam section of the pinion assembly when the crown is pulled out all of the way. The balance keeps running but the second hand is stopped - and if this operation is performed with the second hand within 5 seconds (plus or minus) of the 12 o'clock mark then the cam action will also zero the seconds and hold it there. Perfect for synchronising your watch to a reference signal, this mechanism is a precursor to the simpler electronic zero-resetting incorporated in later Cal 8600 Crystron-era watches.

Close up of sweep second pinion assembly and highlighted in position next to the zero-setting actuators that occupy much of the 'Drive train area' -

![8811%20-%20Hacking%20Mechanism_zps6dvvf6 8811%20-%20Hacking%20Mechanism_zps6dvvf6]()

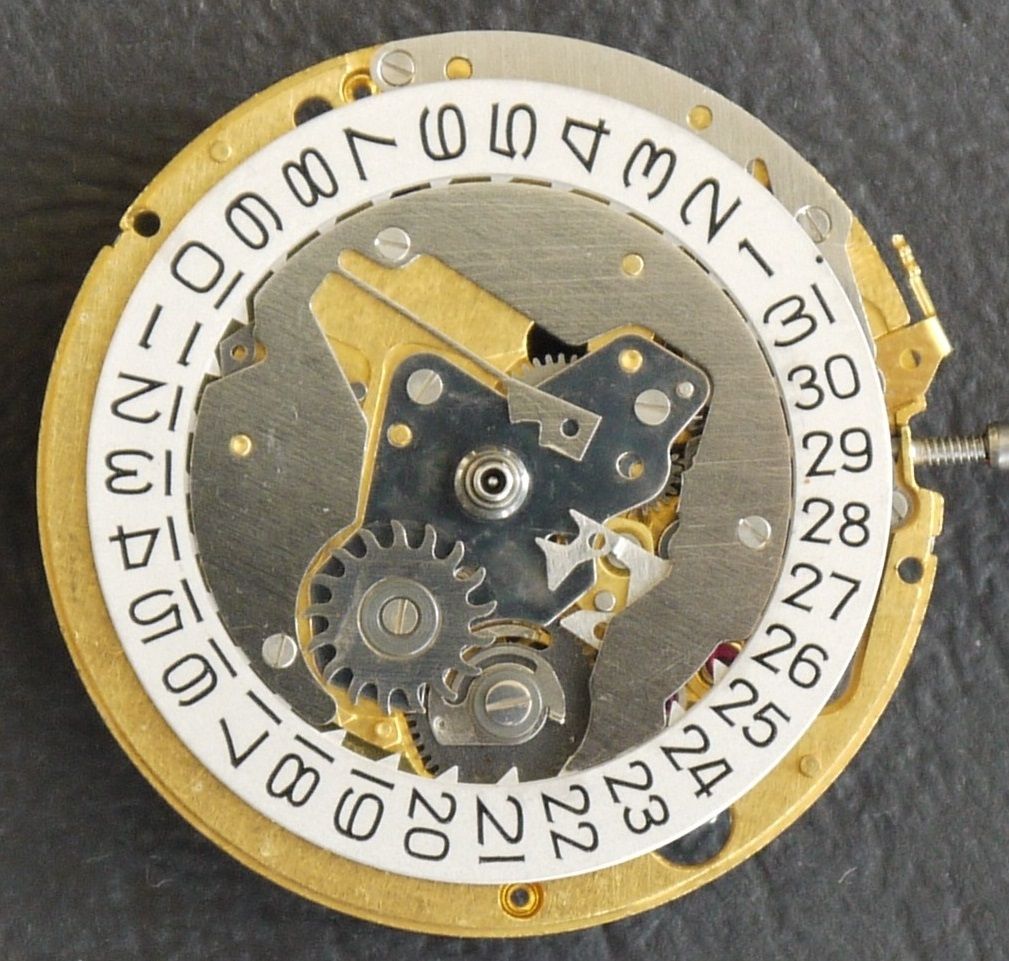

On the dial side there are fast day and date setting mechanisms -

![8811%20-%20Dial%20Side%20Almost%20Comple 8811%20-%20Dial%20Side%20Almost%20Comple]()

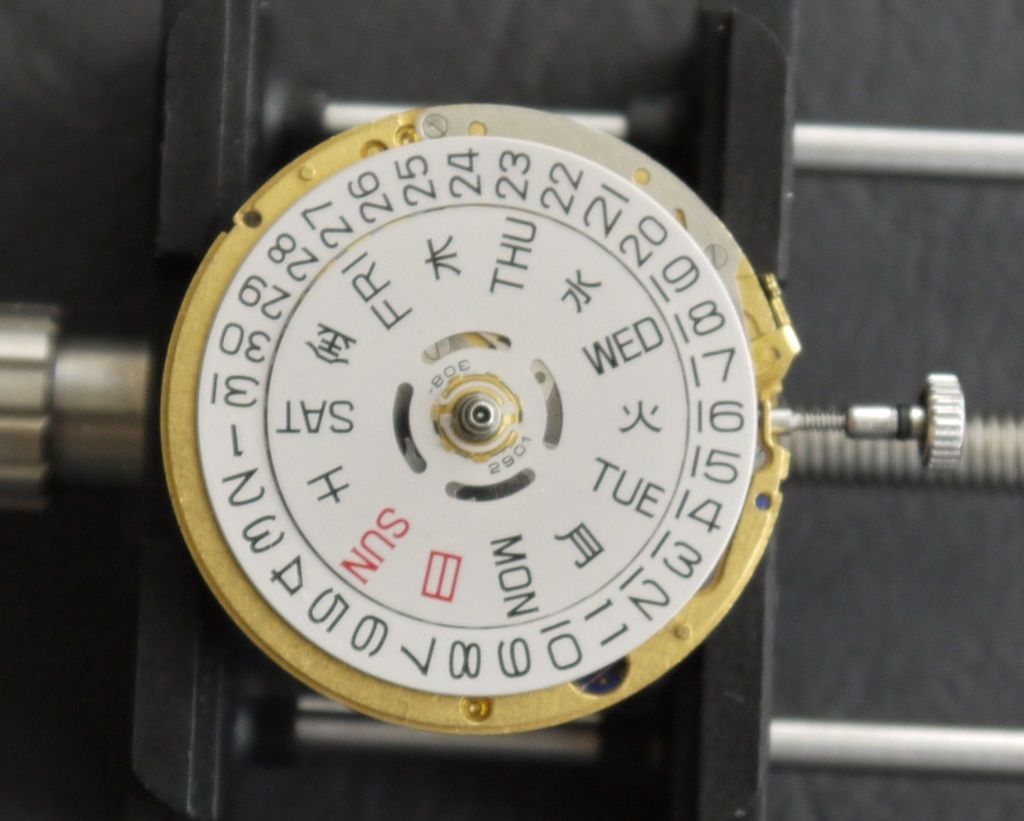

Fully assembled dial side -

![8811%20-%20Dial%20Side%20Complete_zpsjum 8811%20-%20Dial%20Side%20Complete_zpsjum]()

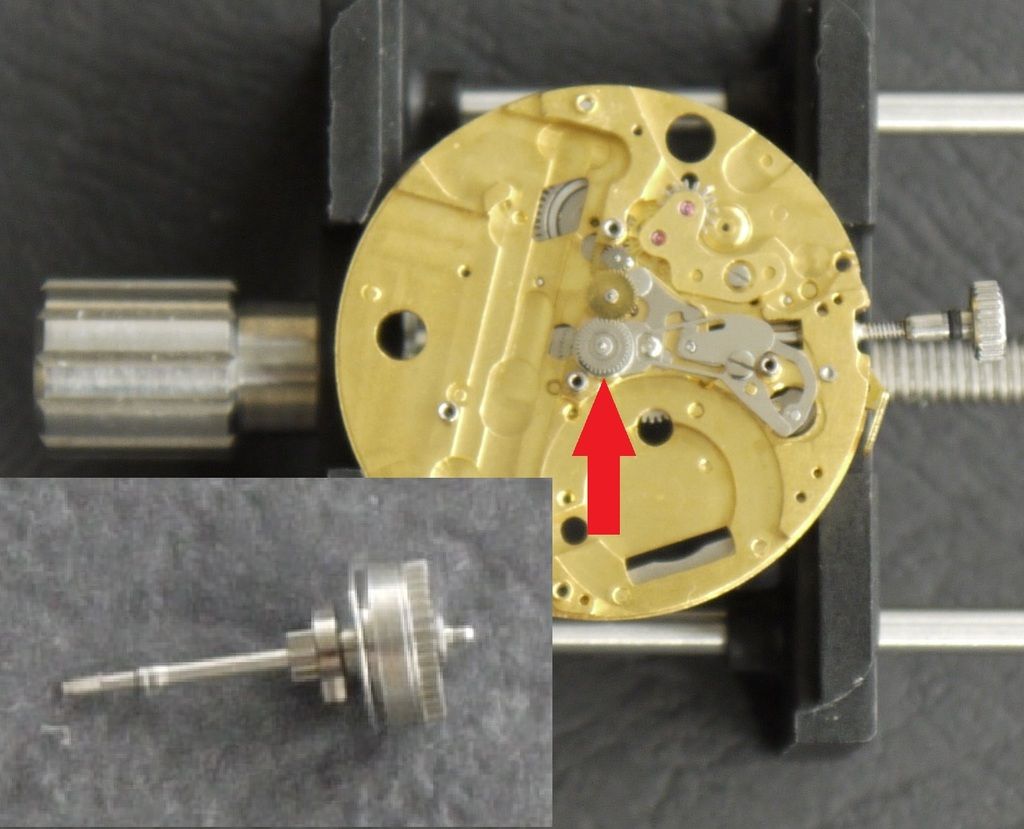

Below is the fully assembled balance side. The large gold contact piece indicated with the arrow is a switch contact that is actuated by battery hatch rotation - it enable the power to be disconnected by turning the battery hatch to the 'OFF' position without removing the battery -

![8811%20-%20Circuit%20Side%20Complete_zps 8811%20-%20Circuit%20Side%20Complete_zps]()

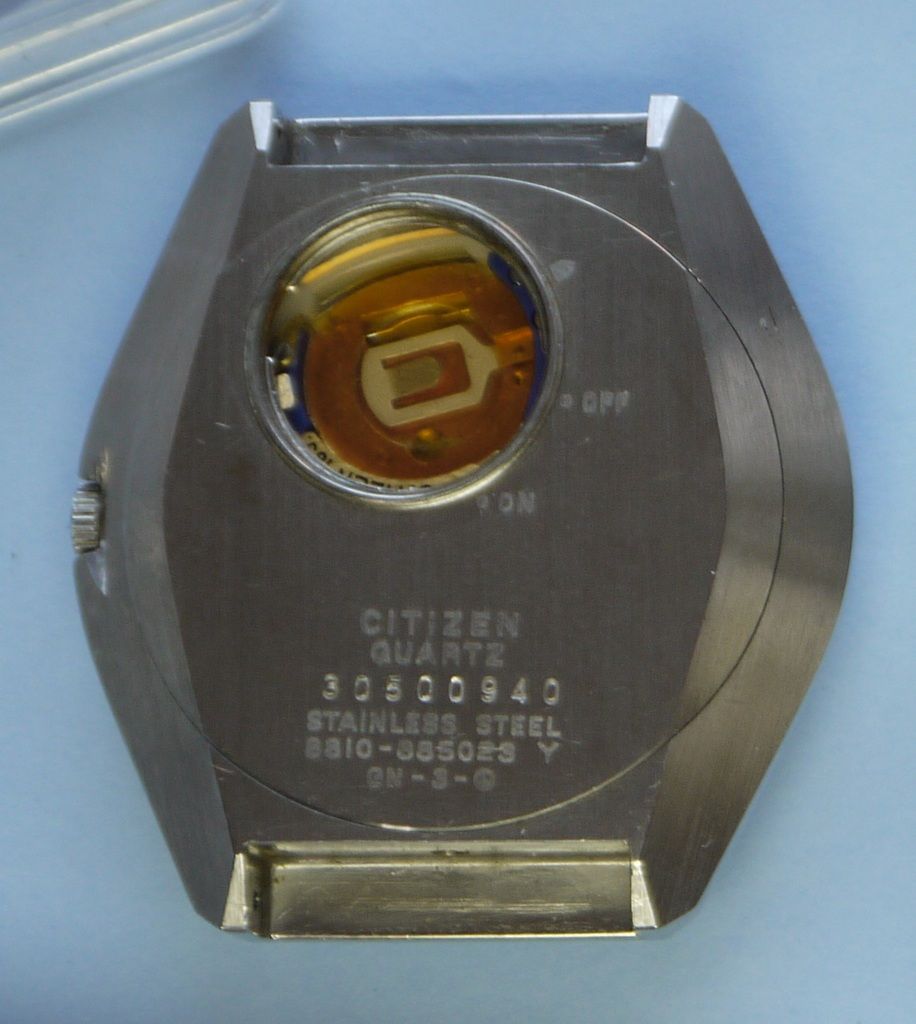

Back cover showing ON/OFF positions of battery hatch switch (the third position is to open/remove the hatch) -

![8811%20-%20On%20Off_zpsqn6wxmtk.jpg 8811%20-%20On%20Off_zpsqn6wxmtk.jpg]()

Here is the rest of the just-serviced watch, for assembly sometime soon - front-loader case / blue dial / white metal hands / spacers etc. -

![8811%20-%20Case%20Parts_zpsyj9deen3.jpg 8811%20-%20Case%20Parts_zpsyj9deen3.jpg]()

For the uninitiated, this is a quartz-controlled balance wheel movement. That means that it uses a battery, quartz crystal and some electronics to drive and regulate the oscillation of a balance wheel which then drives a conventional mechanical drive train. There were only a few manufacturers that made this type of movement but no one made one quite like this Citizen. Unlike some other quartz-controlled balance movements this is a real high-quality thoroughbred . The quartz part is temperature compensated meaning 10s/month accuracy in the 8811 version (shown here) and 5s/month accuracy in the very rare 8810 EFA version. And the mechanical part beats really, really fast...

I've had a brown/gold dial version in my 'A-list' box for a while. Seen here on one of the three original strap types that these watches were available with -

I've had another one waiting in my inbox for service/repair for rather too long - today I stripped it and repaired a couple of faults. So I thought I would take the opportunity to post a few pictures of the movement and to point out a few interesting (for some) technical details.

Citizen describe the coil/balance/index mechanism as a 'resonant motor' - the balance mass/spring has a resonant mechanical frequency and it is forced electromagnetically at this frequency by a coil pair attached to the output of the electronic circuit and four pairs of permanent magnets mounted on the balance. The balance is small and the spring is stiff providing a ridiculous 115200 A/h (16Hz) blur. It doesn't take much dirt or misalignment to stop this thing from running properly. It also provides the kind of smoothly sweeping second hand one usually associates with a hum.

The drive train is extremely compact to allow for the large battery, enormous quartz tube, electronics, coil assembly and ancillary elements. This shows the bare movement plate (balance side) -

Here it is with the complete drive train fitted -

The build quality and design detail is impressive. Coils are elliptical to better couple with the permanent magnets on the rotating balance -

The coil assembly slots in between the two layers of magnets on the balance and must be shimmed accurately with special parts at both ends to the correct position. The balance cock with serial number and markings fits directly on top of the drive train bridge. The regulator can be used to adjust the resonant frequency of the balance and so adjust the AMPLITUDE -

CMOS electronics were provided by Toshiba -

The movement has an unusual escapement much like that found in some early electric watches. There is a roller jewel on the bottom of the balance which directly drives the toothed index wheel. Then there is a small permanent magnet fixed in the movement plate which keeps the index wheel advancing forward in orderly fashion one tooth at a time.

View of the index wheel with permanent magnet highlighted -

The movement contains a rather unusual sweep second pinion assembly with a cam section and a separable clutch. There is an elaborate mechanism that separates the sweep second drive and simultaneously engages a hammer onto the cam section of the pinion assembly when the crown is pulled out all of the way. The balance keeps running but the second hand is stopped - and if this operation is performed with the second hand within 5 seconds (plus or minus) of the 12 o'clock mark then the cam action will also zero the seconds and hold it there. Perfect for synchronising your watch to a reference signal, this mechanism is a precursor to the simpler electronic zero-resetting incorporated in later Cal 8600 Crystron-era watches.

Close up of sweep second pinion assembly and highlighted in position next to the zero-setting actuators that occupy much of the 'Drive train area' -

On the dial side there are fast day and date setting mechanisms -

Fully assembled dial side -

Below is the fully assembled balance side. The large gold contact piece indicated with the arrow is a switch contact that is actuated by battery hatch rotation - it enable the power to be disconnected by turning the battery hatch to the 'OFF' position without removing the battery -

Back cover showing ON/OFF positions of battery hatch switch (the third position is to open/remove the hatch) -

Here is the rest of the just-serviced watch, for assembly sometime soon - front-loader case / blue dial / white metal hands / spacers etc. -